In tin plating, a tin coating is deposited on the surface of the component by applying a voltage to a cathodically connected workpiece. The tin coating features excellent conductivity and solderability and is also food-safe. Tin is frequently used in the electrical industry, but also in the automotive sector (electric mobility, hybrid vehicles), such as for power rails, busbars and connectors.

Tin / tin plating: processes and advantages

Typically, the deposited tin (Sn) layer has a silvery white colour and a soft surface, which can be made either shiny or matt. The tin coating is both decorative and functional at the same time. It forms a natural passivation layer on the surface that already provides a good level of corrosion protection. Optional passivation can be used to create decorative, more stable surfaces in combination with defined contact resistances. Tin coatings also feature excellent conductivity and solderability. Moreover, tin exhibits low contact corrosion in combination with aluminium as well as high temperature stability. The process used offers good throwing power, which means positive results can be achieved even on complex geometries. The lead-free process is RoHs-compliant and provides a food-safe coating. Further advantages of tin surfaces are their chemical resistance, good layer thickness distribution and high ductility.

Components can be tin-plated using both the rack and the barrel methods.

Solderable, conductive, food-safe tin coatings can be applied to a wide range of metals, including aluminium, steel, stainless steel, copper and brass.

Bright tin

Bright tin coatings are fine crystalline and extremely ductile. To reduce and counter the risk of whisker formation, diffusion barrier layers of copper or nickel can be applied.

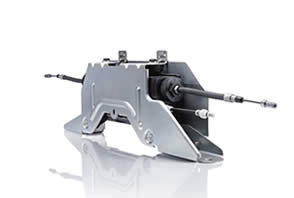

As a coating process, bright tin is ideally suited for electrical parts and current-carrying components that require good solderability. RoHs-compliant bright tin is also a good choice for products that come into contact with foodstuffs. The functional and/or technical coating has a decorative, shiny finish. At the same time, bright electroplated tin has additional lubricating properties, making the process well suited for plug contacts. The method is used in the automotive industry (such as for the power rails of battery systems or for electric motors, busbars and connectors), the household appliance sector, the food industry and applications for current-carrying systems and circuits.

Matt tin

Unlike bright tin, matt tin coatings are low-reflective and have a coarser crystalline structure. The high purity of matt tin coatings offers additional positive characteristics, such as virtually no whisker formation and compatibility with the currently standard leaded and lead-free solders. Matt tin is primarily used in electronics, where there are no optical requirements.

Tin plating is also a suitable process for electric mobility applications – we will be happy to advise you: elektromobilitaet(at)holzapfel-group.com

Holzapfel Group

Holzapfel Group YouTube

YouTube