Zinc-iron plating is a galvanic process for both technical and decorative surfaces.

Zinc/iron coating is a galvanic coating method that, using an alkaline electrolyte, precipitates a zinc/iron alloy with a homogeneous iron incorporation rate ranging from 0.4% to 0.7% on a metallic component. This method results in a very even plating thickness and may be used for industrial and decorative surfaces. Steel and sintered metals are the metals most usually coated. In comparison with traditional zinc surfaces, the corrosion protection is clearly improved, even when the coatings are thin.

Cr(VI)-free passivation in black or transparent is possible after plating. Subsequent sealing results in a further improvement of the corrosion protection.

The Holzapfel Group coats zinc iron according to the following standards: VW TL 153, DBL 8451, BMW G 90010, GME 00252, GMW 0047, DIN 50962. Zinc-iron standardization concerning spay constancy (CrVi-free systems) in hours DIN EN ISO 9227

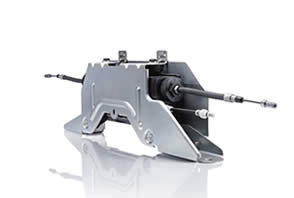

![[Translate to English:] mit Zink-Eisen beschichtetes Bauteil (Blech)](/fileadmin/redakteur/produkte/verfahren/zn_fe.jpg)

Holzapfel Group

Holzapfel Group YouTube

YouTube