Sinter Surface Solutions are a multi-stage process for reliably sealing and subsequently plating porous materials. The process is a key technology for the wider use of powder-metallurgical materials in applications for which a coating is required.

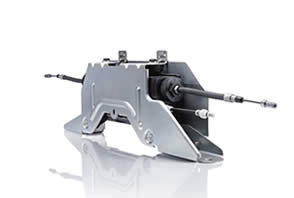

Using Sinter Surface Solutions to impregnate and coat sintered materials: Explanation of the impregnation system

With Sinter Surface Solutions, surfaces are impregnated with special synthetic resins to seal sintered components or porous areas (impregnating sintered materials in synthetic resin). In a vacuum process, the resins are applied to the open-pored, sponge-like structures, where they harden to form a chemically highly resistant, pressure-tight mass (vacuum-synthetic resin process).

Impregnation is the most important step when coating the surfaces of sintered components. Coating is not possible without respectively sealing the pore structure, particularly when close to the surface. A wide range of ferrous- or non-ferrous-based alloys can be impregnated.

After the pores have been closed (sealing), the sintered components are then plated without any of the media used in the coating process penetrating the material. Practically all components manufactured using ferrous-based powder-metallurgical processes can be coated using the well-known corrosion-protecting, decorative and functional processes we offer in our portfolio. With these coatings, once the sintered components have been impregnated, surface protection is extensively guaranteed and numerous optically appealing or functional surfaces can be created at the same time. For instance, it is possible to apply a zinc-nickel galvanic coating on powder-metallurgical materials and also to chromium-plate sintered materials.

Necessity to seal porous areas of sintered components

Sintered materials are used as construction materials in a broad range of applications. They make it possible to manufacture materials that are frequently not feasible using conventional production processes. Sintered materials are naturally porous and therefore often difficult to plate galvanically. If porous materials are not previously sealed, galvanic processes will cause so-called "bleed-out", i.e. the subsequent leaking of galvanic fluids. Sinter Surface Solutions solve this problem by impregnating and sealing the pores of construction materials made of sintered metals and then galvanically coating them. The process reliably prevents bleed-out after galvanising by sealing off the porosity prior to galvanising, painting or coating.

Advantages of sealing powder-metallurgical materials

The process has clear advantages compared with impregnating systems otherwise available on the market, as conventional systems have been developed for cast materials and do not seal off the porosity to the same extent as Sinter Surface Solutions, which have been specially developed for sintered materials. A sintered product treated with Sinter Surface Solutions has a far thinner rim than a sintered workpiece that is impregnated and coated using conventional methods. The pores are filled with resin right up to just below the surface and sealed, making them better prepared for impregnation.

Holzapfel Group

Holzapfel Group YouTube

YouTube