Nickel SulfamateTechnical special nickel plating (electrolytically precipitated nickel out ouf nickel sulfamate) is also known as pure nickel plating, nickel sulphamate or technical nickel.

Nickel Sulfamate: process and advantages

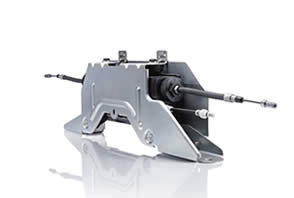

Special nickel plating (10-30 µm) is used for anodes, cathodes and two-pole-electrodes. Other areas of usage are for example parts subject to wear or during the production of injection moulds and die-castings. Special nickel platings could also be used as part of a plating system, acting as a bonding agent between the multiple layers. In addition, the special nickel can play the role of corrosion protection within a plating system.

The pure nickel plating, combined with a special plating under vacuum, is also ideal to gain large surface enhancements for better effectiveness in electric machinery.

Holzapfel Group

Holzapfel Group YouTube

YouTube