Innovative anodising process for aluminium surface finishing

Anodising (Eloxal): Processes and advantages

Eloxal stands for the electrolytic oxidation of aluminium, which is a process used for treating the surfaces of light metals. Anodisation converts the surface of the basic metal into a dense oxide layer, giving light metal components (made of aluminium) a tough, corrosion-resistant protective layer. Depending on the desired finish, either protective anodisation (protects from corrosion) or other anodising processes that meet higher optical standards can be used.

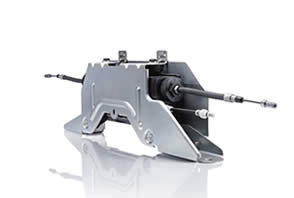

The Holzapfel Group offers a variety of enhanced forms of the conventional anodising process to produce anodised aluminium surfaces suitable for a broad range of applications. In addition to anodisation in a variety of colours and anodisation with individual visual designs, a process for treating hybrid components (metal-plastic composites) is now available, too. We have also developed a partial anodising process.

Holzapfel Group

Holzapfel Group YouTube

YouTube