Decorative and protective surfaces – copper

High-gloss, ductile layers with fine crystals are precipitated in an electrolytical process. Both acidic and cyanidic electrolytes are used. Copper has good covering properties and is mostly used as a substructure for other galvanic surfaces such as nickel and chrome. Cu/Ni and Cu/Ni/Cr coating systems fulfil numerous requirements in terms of corrosion protection, while providing a decorative appearance. Copper is often also used as an independent, functional or decorative plating. In addition to standard substrates such as iron and Cu-Zn materials, zinc die cast parts, powdered metals and aluminium are also plated.

Copper

- Clear levelling effects, good pre-treatment for ZN die-cast or sintered moulded components.

- Very good heat conductivity

- Excellent electrical conductivity

Copper surfaces have a decorative, reddish surface, which can be subsequently dyed if necessary. Once it has been given an antique finish, this creates an attractive and wear-resistant top coat.

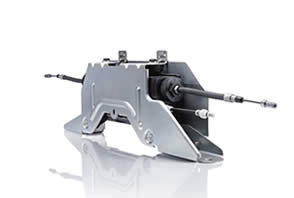

- Automotive (frequently used are Cu/Ni or Cu/Ni/Cr coating systems)

- Consumer industry (household implements, as substructures or coating systems)

- Electrical industry

- Mechanical engineering

Holzapfel Group

Holzapfel Group YouTube

YouTube