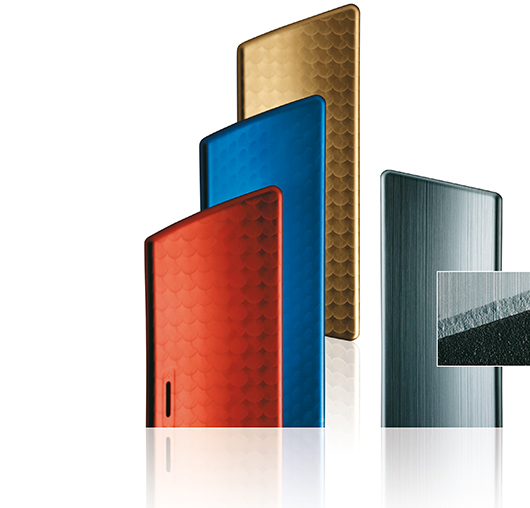

Hybrid components and also metal-plastic composites in which genuine metal surfaces are applied to plastic components are in high demand for applications such as vehicle interiors in the automotive industry. They unite the advantages of lightweight construction with the visual and haptic elegance of a metal surface.

With Anodised Individual Hybrid, the Holzapfel Group offers its customers a process that is ideally suitable for surface finishing on components back-injected with plastic that need to have a highly decorative look. Anodised Individual Hybrid makes it possible to coat complete hybrid composite parts with the advantages of the “one way” value-added process. The parts are coated in an anodising process. The dyes are then individually embedded in the pores of the anodised surface in a final stage of the production process, ensuring a high level of quality. The production sequence prevents the anodised layer from becoming ruptured by processes such as back-injecting or gluing performed after coating.

Holzapfel Group

Holzapfel Group YouTube

YouTube