Zinc-Nickel fleXXcor is a flexural, ductile and bendable Zinc-Nickel plating with highest corrosion protection and is used for parts with special needs such as pipes and oil- or fuel pipings.

Flexible Zinc-Nickel-fleXXcor: process and advantages of the bendable Zinc-Nickel plating

Zinc-Nickel fleXXcor is bendable after plating and yet highly corrosion-resistant. The surface is an electrolytically deposited Zn-Ni alloy plating with 12-15% nickel. And with a layer thickness of only 6- 10 µm it fulfills high corrosion protection requirements. Through the usage of a special electrolyte along with tightly managed bath proportions, the Zn-Ni fleXXcor treatment purposefully alters the crystal structures and particle sizes of the precipitated layer. This creates a pliable Zn-Ni alloy plating and a ductile surface. The Znni layer boasts good thermic capacity and is typically applied on base materials made off steel. Furthermore zinc-nickel fleXXcor fulfills all norms in the automotive industry and is free of Chrome-VI. The electrodeposition is conducted on the rack.

Bending after plating

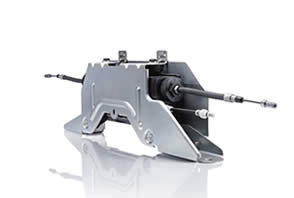

The flexural Zinc-Nickel plating is not only suitable for pipes and oil- or fuel pipings. For metal sheet parts to be shaped after plating such as magnet casings, the surface also offers as broad range of benefits.

The key advantage is the fact that bending and forming can take place after the plating process. Pipes, oil- and other fuel pipings can thus be coated in their original unbent shape obviating the need to block the piping due to geometry. Thus handling efforts are decreased and cost savings are realized. Moreover, metal sheets that are bent after coating, such as spindle tubes and magnet casings, can benefit from this treatment as well. Transparently passivated Zn-Ni treated parts currently on the market can be bent, however, the bending process typically damages the plating and causes the coat to flake off. Parts that had to be bent or creased after plating out of technical reasons (i.e. magnet casings) would lose their corrosion protection at that point. With the pliable Zn-Ni fleXXcor treatment high corrosion resistance (720 hours without red rust during salt spray test) is still fully present after the bending process. At the same time, the life cycle of the bending and creasing tools are extended due to no or very little abrasion of the ductile Zn-Ni layer.

Holzapfel Group

Holzapfel Group YouTube

YouTube