Electroplated zinc is the most economical and effective treatment for functional and decorative corrosion protection.

Zinc plating: process and advantages

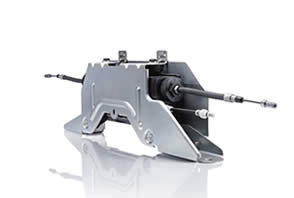

The zinc layers have a metallic, bluish/white colour with high gloss. Components can be plated on the rack as well as in the drum. The most important technical property of zinc platings is their corrosion resistance. Steel components with a zinc plating are well protected against red rust. If no further protective measures in the form of subsequent treatments are taken, the zinc surface will soon show signs of corrosion (so-called "white rust"). As zinc has a negative potential in relation to iron, it is suitable as a sacrificial anode for cathodic corrosion protection of iron alloys (remote protective action). In comparison with other plating systems, zinc also has the advantage that, even if the coating should be damaged, the base material is not affected, i.e. no rust forms underneath the plating.

The Holzapfel Group plates zinc according to the following standards: VW TL 217, DBL 8451, GME 00252, GMW 4700, BMW GS 900100 and DIN 12329 or 50961. Zn standardisation with regard to salt spray resistance (Cr(VI)-free systems) as per DIN EN ISO 9227. The substrate materials used are usually steel, cast iron and powdered metals.

Holzapfel Group

Holzapfel Group YouTube

YouTube