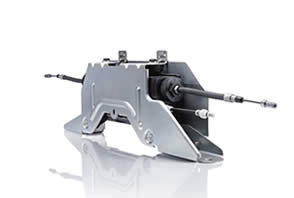

Process technology electroplates individual components within seconds – exactly reproducible and in outstanding quality with total process reliability

High-speed electroplating: processes and advantages

Our process technology makes it possible to electroplate each component individually, perfectly and cost-efficient – right down to the last detail. Both the plating and the entire plant technology are precisely designed to meet your component specifications. We can provide you with selective platings and varying layer thicknesses on the same component. Our process technology can be applied to practically all metallic electroplated surfaces.

Control and documentation of the process parameters during series manufacturing results in perfect components every time – ensuring outstanding quality and process reliability. We can also perform a fully automated 100% check for previously agreed characteristics, e. g. dimensions or optical inspections.

Our efficient technology, which plates every single component within seconds, is an ideal solution for high-volume production scenarios and guarantees exactly reproducible tolerances.

We specially develop and engineer the systems you require to individually electroplate your component at high speed. The entire technology, including the plating process, is individually tailored to meet the specifications of your component. We offer surface treatment as a service.

Further information

- www.fpp-srl.com

- Watch our film on fast plating technology: https://youtu.be/eJBqyZkbktE

Holzapfel Group

Holzapfel Group YouTube

YouTube