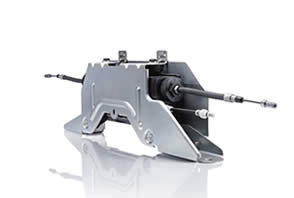

The electrolytic plating process zinc-nickel stands out with very good corrosion protection and a high thermal resistance.

Zinc-Nickel Plating: process and advantages

Zinc-nickel platings were developed as a result of increasing requirements with regard to corrosion protection, in particular from the automotive industry, against exposure to temperature, road salt and climatic conditions. Zinc-nickel platings are normally used if the traditional zinc-plating process is insufficient, due to high temperatures or aggressive environmental conditions. The Ni incorporation rates amount to approximately 10-15%. The ZnNi surfaces offer optimal cathodic corrosion protection and are highly resistant to thermal loads (up to 120 °C). This type of surface finish is usually used on steel, ferrous cast components and powdered metals. We offer the electrodeposition both as rack plating and as barrel plating.

The Holzapfel Group plates zinc-nickel according to the following standards: VW TL 244, DBL 8451, Opel GME 00252, GMW 0047, BMW GS 90010 and DIN 50962. Zinc-nickel standardization concerning spray constancy (CrVI-free systems) in hours DIN EN ISO 9227.

We offer various Cr(VI)-free post finishing treatments for zinc-nickel surfaces:

- Passivations are available in black or transparent form.

- Top coats (sealing) are optional, but not always necessary. Various systems are used, including those with lubricant additives. In the event of special requirements for corrosion protection, we recommend transcor, a transparent Zn/Ni surface that offers the best results without sealing.

- Preservation of uncoated internal surfaces, for example the inside of pipes, as well as heat treatments (tempering) to remove hydrogen after the coating process, are offered to complement our range.

Holzapfel Group

Holzapfel Group YouTube

YouTube